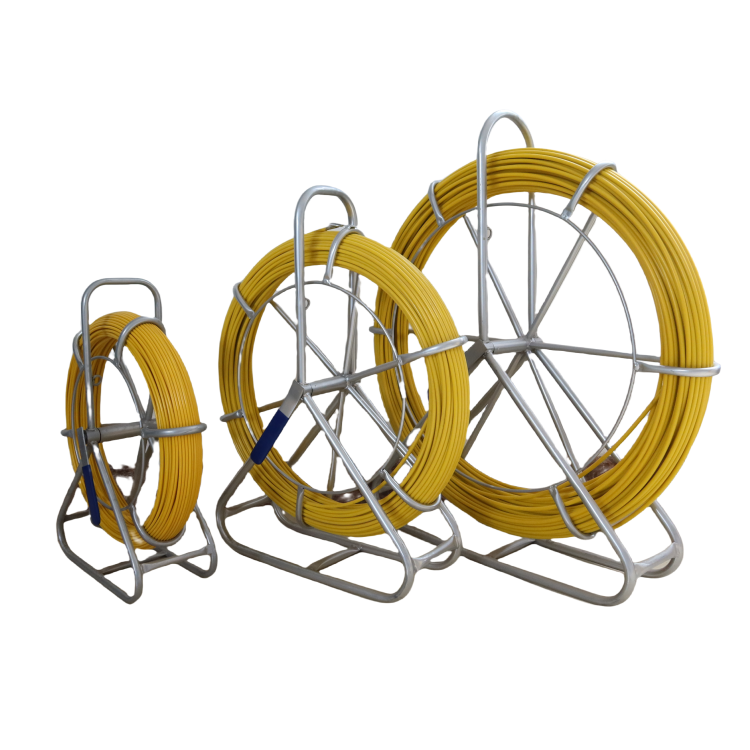

The Making of a Premium Fiberglass Duct Rodder

introduction

The exceptional performance of a professional-grade duct rodder is a direct result of controlled manufacturing. Unlike simple tools, its strength and flexibility are engineered through specific processes that ensure consistency and reliability. This overview walks through the essential steps that transform raw materials into a dependable tool.

1. Raw Material Selection: The Foundation

Quality begins with the choice of raw materials.

Fiberglass Roving: The core is made from continuous, high-tensile fiberglass filaments. Their uniform quality and alignment are crucial for consistent strength.

Resin System: A thermosetting resin, such as vinyl ester, binds the fibers. It is chosen for its toughness and excellent adhesion to glass.

Protective Coating: An outer layer, often made from durable ABS plastic, is applied later to provide abrasion resistance and protect against moisture and impact.

2. The Core Process: Pultrusion

The defining step is pultrusion, which forms the rod's strong, lightweight core.

Impregnation: Fiberglass strands are fed through a bath of liquid resin, ensuring complete saturation.

Shaping and Curing: The saturated fibers are pulled through a heated, precision-shaped die. The heat triggers the resin to harden (cure) into a solid, rigid profile with the fibers locked in place.

Cutting: The continuous, cured profile is cut to the required rod lengths.

3. Coating and Assembly

The pultruded rod is then finished for real-world application.

Applying the Jacket: The rod receives its protective outer coating, typically through a secondary extrusion process that bonds a seamless polymer jacket to the core.

Tip Attachment: High-strength metal tips are securely attached to the ends, usually via adhesive and mechanical locking, to withstand pulling forces.

4. Rigorous Quality Validation

Before leaving the factory, the rodders undergo strict testing.

Tensile Strength Test: Samples are pulled to failure to verify the break strength meets the specified rating.

Flex and Memory Test: Rods are repeatedly bent around a mandrel and released to confirm they return straight, proving resistance to permanent deformation.

Abrasion and Environmental Checks: Tests may be conducted to ensure the coating's durability and the material's resistance to aging factors.

Conclusion

The manufacturing of a premium duct rodder is a streamlined yet precise engineering process. Each stage—from material selection and pultrusion to coating and final validation—is designed to build in reliability. This controlled production results in a tool whose performance is predictable and professional, justifying its value as a long-term investment for demanding electrical and utility work.

References

1. Jinhx. (n.d.). Fiberglass Rod Production Process - Pultrusion. Retrieved fromhttps://www.jinhx.com/news/fiberglass-rod-production-process-pultrusion.html(Describes the pultrusion process for fiberglass rods).

2. Creative Composites Group. (n.d.). The Pultrusion Process. Retrieved fromhttps://www.creativecompositesgroup.com/learning-center/the-pultrusion-

process/ (Explains the standard pultrusion manufacturing steps for composites).

3. ASTM International. *ASTM D3917 -Standard Specification for PultrudedShapes*.(Governs dimensional tolerances for pultruded profiles).

4. ASTM International. *ASTM D790 - Standard Test Methods for FlexuralProperties*. (Covers standard testing for flexural strength, relevant to bendperformance)